Oil Mill

When the olives have been picked and gathered correctly, it is just as important that they are transported to the oil mill with all precautions taken (preferably in ventilated crates) and as quickly as possible. The olives are then processed within 24 hours from delivery.

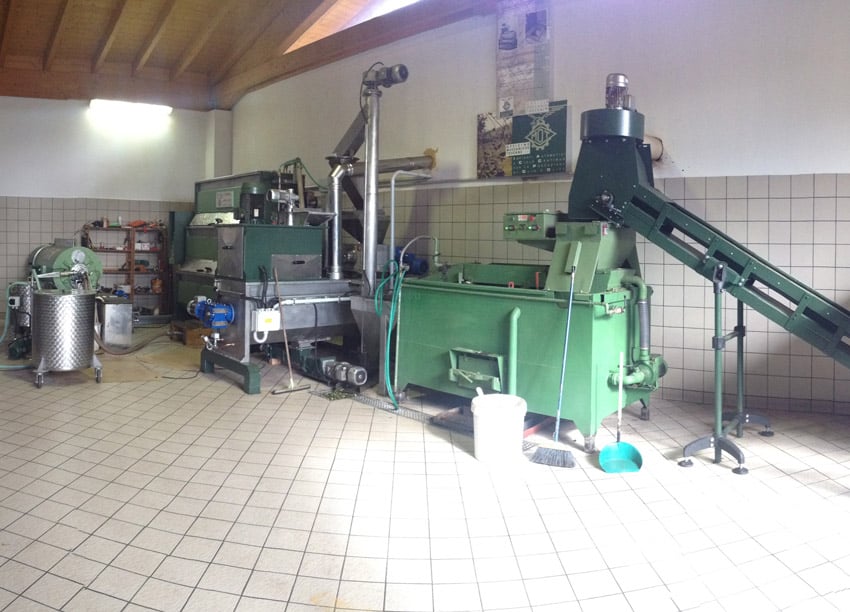

The olives are subjected to several important operations before proceeding with the pressing phase: they are separated from the foliage through automatic machines, which is extracted by suction, and then washed with water to eliminate residues and impurities.

At this point, we pass onto pressing and kneading. These are operations which, one after the other, lead to attainment of the olive paste from which the oil will be extracted.

Following this important moment, we pass to the last process, extraction. This phase allows the definitive separation of the three components: pomace, vegetable water and oil. The oil obtained at the end of this operation is cloudy and opalescent. It is then subjected to filtering, which gives it a clear bright colour and increases shelf life.

The vegetable water is disposed of in special cisterns and transformed in compliance with strict health rules. The pomace is separated from the olive pit through relevant machinery. The pomace residue is spread around our olive groves as a fertilizer. As the olive pit is the woody part of the fruit, it is an excellent fuel and is used on the estate to heat the oil mill. Every component is recycled and transformed according to nature, without damaging the environment.

At this point, the “new” oil is ready to be consumed.

During the first phase, a hammer crusher crushes the olives. The mixture of pulp, olive pit and skin obtained is transported into the kneading machine. Kneading, an essential and very delicate process, makes the oil molecules present in the fruit join together in a way that they can then be separated from the other components. Controlling the temperature and processing times is essential so as not to damage the olive paste. Our plant is made up from four closed stainless steel tanks or kneading machines. Steel is a material that does not emit odours or tastes and is easy to wash. Closure of the tanks prevents oxidation, which would damage the oil.